|

| HOME SERVICES/SITE MAP CONTACT US |

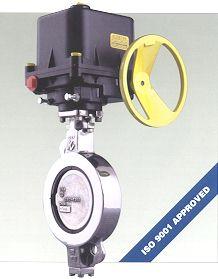

K-LOK High Performance Butterfly Valve Sizes 2 to 12 inch ANSI Class 150 |

|

General Applications |

High performance applications such as steam, chill water, water, utility lines, gasoline, natural gas, air, oil, jet fuels and process lines. |

|

Size Range: 2-inch (50 mm) through 12-inch (300 mm) Rating: ANSI Class 150Materials of Construction: Body: Carbon Steel or 316 Stainless Steel Disc/Stem: 316 Stainless Steel/17-4PH Seat: RTFE or TFE with TFE Encapsulated FKM* 0-ring as standard

*Fluoroelastomer |

|

Stem Bearings: 316 Stainless Steel Body: Stainless Steel/DU Carbon Steel Body: Carbon Steel/DU Pressure Rating: 285 psi bidirectional, dead-end Temperature Rating: Standard: -20 degrees F to 350 degrees F |

Features and Benefits •Heavy duty circular key holds the seat and retaining ring in place, providing bidirectional, dead-end service at full-rated pressure. This eliminates the need for easily corroded and hard-to-remove retention screws. •Uninterrupted gasket surfaces eliminate problems associated with seat retaining screws in the gasket surface and allows use of standard spiral wound gaskets. •Laylength conforms to MSS-SP-68 and can be configured to ISO 5752 short for PN25 pressure rating. •Unique interference seat design with energized elastomer 0-ring allows Class VI shutoff at lower pressures. The seat is further energized by line pressure, providing the same tight shutoff at full-rated pressure. •Valve stem, designed to API 609 standards, protects against blow out. •Adjustable packing utilizes unique rocker-shaped gland bridge that compensates for uneven adjustment of gland nuts. Optional non- adjustable packing offers an economical alternative. •Extended neck allows for two inches of clearance for insulation. •Seat retaining ring is housed within the flange gasket I.D. to eliminate potential emission path. •Variety of material trims allows use in various specific applications and services. |

|

VARCOfor all your valve needs. |

Please feel free to contact us with any questions about our products. Thank you for visiting! VARCO |

|